presentation of compacting

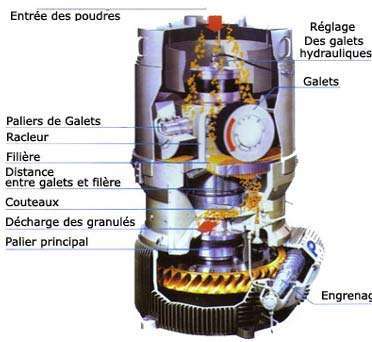

The compacting principle (one pack)

Compacting is the agglomeration of a homogeneous mix of powders by melting one of the masterbatchs (the binder). This melting is carried out by applying pressure to the mix on the draw-plate.

The main advantage of compacting (one pack or blend) is the absence of polymer in the final formulation.

This presents the following advantages :

- Reduction of the final cost

- Improvement in productivity

- Improvement of work and safety conditions (no handling of powder and absence of dust)

- Increased proportioning accuracy resulting from a constant ratio of the various masterbatchs

- Possibility of incorporating liquid masterbatchs

- Constant and regular feeding

- Good dispersion within the polymer during transformations.

Polytechs' goal is to implement the formulations of each of our customers. It is a service that we offer solely as toll compounding.

For complex formulations, Polytechs offers an alternative by carrying out this time of mixture by extrusion

Just as is the case for any toll compounding given to Polytechs, customers may freely choose their masterbatch suppliers.

Examples of compacting produced by Polytechs

- Antioxidants / Organic phosphites with metallic stearates

- Erucamide / Silica with antioxidants / Organic phosphites

- Nucleating agent, with antioxidants / Organic phosphites and metallic stearates

- Chlorinated paraffin and antimony trioxide

- One-pack stabilisation for PVC

- Azodicarbonamide-based formulas

- High-concentration of mineral fillers

- Liquids may be added to the formulas

ENGLISH

ENGLISH

FRANCAIS

FRANCAIS DEUTSCH

DEUTSCH ESPAÑOL

ESPAÑOL